An Overview of the MEMS Accelerometer Applications and Features

An increasing number of the

condition-monitoring items are now making use

of the microelectromechanical system,

also known as the MEMS accelerometer that is

considered to be the core sensors. The MEMS systems are highly-integrated,

economical solutions which help to lessen

the cost of ownership and deployment. The MEMS accelerometers have several benefits, but their utilization

for the purpose of condition monitoring is limited to different applications

which can carry the low-cost bandwidth. Generally, the diagnostic applications need

lower noise over bandwidths beyond frequency ranges of 10 kHz.

The low noise accelerometers are available

everywhere, although few are restricted to certain kilohertz bandwidth level.

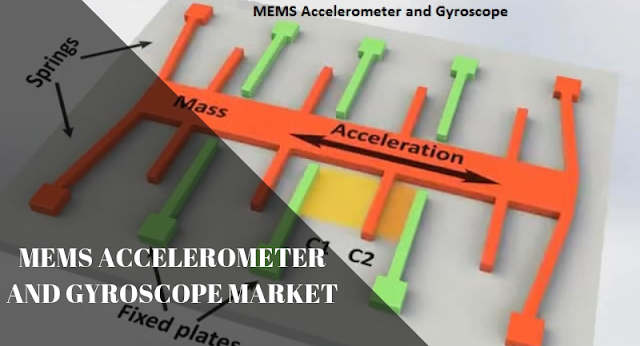

The MEMS devices are mainly based on the

built-in semiconductor fabrication and solid-state electronics facilities since

they offer one with valuable and compelling benefits for the condition

monitoring products.

Features of the MEMS accelerometers:

·

Size and weight- For various

airborne applications, weight converts into the higher cost of fuel as much as thousand

dollars per pound. With various sensors that are

generally deployed on the platform; a light

sensor could mean lower cost of fuel. The MEMS equipment makes it easier for

managing to a digitalized interface which could help you in handling the weight

and cost of the cables.

·

Stability- The MEMS equipment

has proved to be one of the robust devices even in different challenging

environments. It is a device that is specifically designed for measuring the

gravity vector. The MEMS accelerometer helps in maintaining the output noise

density.

·

Scalability- MEMS-based sensors

provide one of the biggest benefits for

scaling up the manufacturing process. This manufacturing capability that

resides in the semiconductor fabrication facilities for signal-conditioning

chip and MEMS sensors; is available to both aviation and industrial

applications.

·

Proven performance- Excellent

reliability and lower cost of MEMS sensors enables better and safer handling of

automobiles, because of which the automotive systems make higher usage of the inertial MEMS sensors. The MEMS sensors

would detect crashes which may come from any direction. High-stability and gyro

accelerometers are the key sensors in the vehicle safety control systems.

The MEMS condition monitoring and its future

At present, there is a huge investment made

in the MEMS technology for its various applications that need higher performance. In addition to the

wide array of attractive features, the MEMS inertial sensors help in dealing

with the quality issues that plague other architectures and materials. The MEMS

inertial sensors are mainly used in aviation, automotive applications, thus

demonstrating a newer track of delivering reliability and high-quality. It is

anticipated that the MEMS device and its performance would continue to enhance

dramatically, thus offering a new generation of wireless and smart sensors along

with a low-cost integrated system. With

the rise in the demand for this technology, the Global

MEMS Accelerometer and Gyroscope Market would gain traction in the

forecast period.

Comments

Post a Comment